Belt Conveyor

What is the belt conveyor?

Belt Conveyor: An Essential Tool in Industrial Processes

The belt conveyor, a cornerstone of many industrial processes, is a mechanical engineering solution that has revolutionized the way we transport raw materials, products, or goods. This versatile equipment can cover distances up to 2 kilometers, making it an integral part of various industrial processes.

Belt conveyors are engineering marvels that transport materials and goods across various industries. They consist of a flexible strip, typically made of durable materials like nylon or rubber, powered by an electric motor that moves them along a predetermined path.

Industries such as food processing, logistics, mining, and construction heavily rely on conveyor belts. They offer an efficient way to transport materials from one point to another, thereby increasing productivity and reducing labor costs.

The advantages of conveyor belts are manifold. They offer speed, efficiency, and adaptability to different environments. Furthermore, they allow for precise material direction, reducing the risk of damage during transportation.

Main advantages of belts conveyor:

- Cost-effective transportation within various industrial processes.

- Reduction in manpower, often replacing human labor.

- Elimination of human error.

- Ensures regularity and stability of transport and circulation rates.

- Facilitates integrated automatic control of industrial processes.

- Aids in digital transformation and the use of modern artificial intelligence methods.

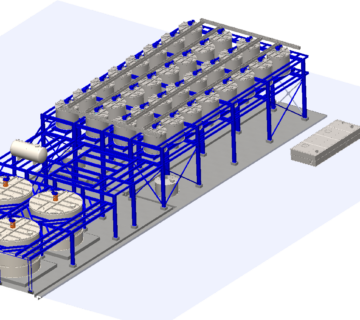

NDESCO factory for fabrication of steel structure, handling equipment & production lines.

Call Naw: +002010 2828 0708

Belt conveyor components:

A belt conveyor system is made up of several key components that work together to transport materials from one place to another. Here are the main components of a belt conveyor system in detail:

- Conveyor Belt: The conveyor belt is the heart of the system. It is a continuous, flexible strip made from a durable material like rubber, nylon, or polyester. The belt is looped over pulleys at each end and is driven by one or more drive units to move materials along its length.

- Head Pulley (Drive Pulley): Located at the discharge end of the conveyor, the head pulley is wrapped in a rubber lagging to increase friction for drive traction. It is connected to the drive motor and gearbox to power the conveyor belt.

- Tail Pulley (Idler Pulley): Located at the opposite end of the conveyor from the head pulley, the tail pulley functions as a guide for the conveyor belt to run around. It can be adjusted to maintain belt tension and alignment.

- Drive Unit: The drive unit consists of an electric motor and a gearbox that provide power to the head pulley and, in turn, the conveyor belt. The size and power of the drive unit depend on the load and speed requirements of the conveyor.

- Take-up Unit: This component adjusts the tension of the conveyor belt to prevent slippage on the drive pulley. It also compensates for variations in belt length due to temperature and load changes.

- Rollers: These are cylindrical components that support the conveyor belt and provide a smooth surface for it to run on. There are different types of rollers, including carrying rollers (support the belt and load), return rollers (support the return side of the belt), and impact rollers (absorb the shock of heavy loads).

- Frame: The frame supports all the components of the conveyor. It is typically made of steel or aluminum and includes a structure for mounting the head and tail pulleys, the take-up unit, and the rollers.

- Bearings: Bearings are used in the pulleys and rollers to reduce friction and facilitate smooth rotation.

- Accessories: Various accessories are used in a conveyor system, including side skirts (prevent spillage of material), sensors (Zero speed, Drift Switch, Emergency stop switch…etc.)), and scrubbers (clean the belt).

Each of these components plays a crucial role in the operation of a belt conveyor system. The design and configuration of these components can vary depending on the specific requirements of the application.

Types of belt conveyors:

Belt conveyors come in a variety of types, each designed for specific kinds of applications. Here are some of the most common types of belt conveyors:

- Flat Belt Conveyors: These are the most common type of belt conveyor and are very versatile. They use a flat, continuous belt that runs on pulleys at either end of the system. Flat belt conveyors can transport a wide variety of materials, from small components to larger items.

- Roller Bed Conveyors: In these systems, the belt runs over a bed of rollers. They are typically used for transporting heavy items, as the rollers reduce the friction that the belt would otherwise encounter. This makes it easier for the conveyor to move heavy loads.

- Incline/Decline Belt Conveyors: These are used to transport materials up or down an incline. They are similar to flat belt conveyors, but with added cleats on the belt to prevent the materials from sliding down the incline.

- Slider Bed Conveyors: These conveyors have a flat surface (instead of rollers) that the belt slides over. They are typically used for lighter loads and shorter distances.

- Magnetic Belt Conveyors: These conveyors use a magnetic belt to hold and control ferrous objects. They are commonly used in recycling plants and other industries where metal objects need to be moved.

- Wire Mesh Belt Conveyors: These conveyors use a wire mesh belt instead of a flat belt. They are often used in industries such as food processing and manufacturing, where the conveyor needs to be resistant to heat, chemicals, or oils.

- Troughed Belt Conveyors: These conveyors use a belt that forms a trough on the carrying side. This design allows the conveyor to carry more material than a flat belt conveyor. They are commonly used in the mining industry to transport bulk materials.

- Plastic Belt Conveyors: These conveyors use a plastic belt and are often used in food processing and packaging applications. They are easy to clean and resistant to chemicals.

Each type of belt conveyor has its own advantages and is best suited to certain kinds of applications. The choice of conveyor depends on the specific needs of the operation, including the type of material being transported, the distance it needs to be moved, and the conditions under which the conveyor will operate.

Applications of belt conveyor:

Belt conveyors are systems that use a continuous belt to transport or move items from one point to another. They have many applications in different industries, such as:

- Food industry: Belt conveyors can be used to convey raw materials, processed foods, packaged products, etc. in food processing plants, bakeries, restaurants, etc. They can also be used for sorting, grading, inspecting, and washing food items.

- Aviation industry: Belt conveyors can be used to transport luggage and cargo in airports. They can also be used to load and unload airplanes.

- Transportation industry: Belt conveyors can be used to move passengers and vehicles in train stations, subway stations, bus terminals, etc. They can also be used to transport coal, ore, sand, gravel, etc. over long distances or gentle slopes.

- Manufacturing industry: Belt conveyors can be used to move parts, components, materials, finished products, etc. in assembly lines, production lines, warehouses, factories, etc. They can also be used for quality control, testing, packaging, etc.

- Other industries: Belt conveyors can be used for various purposes in other industries, such as mining, agriculture, recycling, pharmaceuticals, printing, etc.

NDESCO factory for fabrication of steel structure, handling equipment & production lines .

Call Naw: +002010 2828 0708